This summer, INOSIM will be 20 years old. We look back on an eventful and, most of all, steadily innovative past. The company founder’s idea to supply the process industry with a powerful simulation software has become a real success story. Follow us on a journey through time:

Timeline

2000: A Simulation Desert

At the start of the new millennium, the German and European process industry was a giant. But in terms of digital technologies and methodologies, it was still a dwarf. Peter Balling, an experienced sales engineer dealing with software for industrial material flow analysis, had a vision at that time: He would combine engineering and process development, the entire process engineering plant, in one simulation tool, in a way as detailed and dynamic as possible. Such a tool would save millions in the development and optimization of production facilities. The advantages of process simulation: No more oversized plants that consume energy unnecessarily; no more suboptimal processes that consume resources without even delivering the best possible product quality.

2003: Foundation Of INOSIM

In 2003, INOSIM GmbH was founded. It developed and marketed its first product, the simulation software INOSIM Batch. A lot of convincing was needed with potential customers: What exactly is process simulation, why do we have to do this elaborate work? We have our experience, Excel lists or simple tools to plan production and processes! With a lot of commitment and expertise, INOSIM was able to win more and more customers for the innovative simulation software. The big players in the European process industry were in right from the start, as well as some highly specialized engineering companies. But the software also played an early role in renowned research projects and in university education.

2006: INOSIM Bio Project Start

The many years of experience of INOSIM GmbH should now also flow into the development of an innovative simulation environment for the biotechnology industry. The new tool had to be able to map biotechnological production processes using specific calculation models. The development was based on a two-year research project (2006-2008) funded by the German Federal Environmental Foundation (DBU). The project partners were INOSIM, the Technical University of Dortmund, and bitop AG (Witten) as an application company. The project objectives were the process optimization in the applying company, an increased sustainability of its production and the integration of the innovative simulation application into the product life cycle (PLM). With the help of the simulation, optimizations of the manufacturing process were developed during the course of the project, which led to significant savings in wastewater (- 38%), salt (- 17%) and energy consumption (- 17%). Production costs decreased by 26 % and output increased by 27 % (read more in our case study).

Since then, INOSIM has been involved in numerous other research projects. More information about our research participations can be found in the Research area of this website.

2010: INOSIM Consulting Founded In Dortmund, Germany

The successful research project INOSIM Bio gave rise to the idea of offering software and services from a single source. As a result, in 2010, INOSIM Consulting GmbH was founded in Dortmund. Since then, the office in Joseph-von-Fraunhoferstr. 20, 44227 Dortmund, has become our main location. Here, motivated process engineers offer high-quality simulation-based consulting for the process industry as well as diverse, continuously developed training programs for the software. Thus, all INOSIM customers have the choice: Purchase the software and train your staff or have simulation models created and evaluated by our consultants. Software support is also in the hands of INOSIM Consultants, who thus also act as the link between users and software development.

2011: The First INOSIM User Day

The event focuses on the exchange between INOSIM users and features insight into our development and interesting contributions by our customers. Current questions from practice, but also scientific innovations or impulses for software development are regularly discussed here. As a result, many customer requirements have already been directly incorporated into the development of our products. Each User Day is framed by an attractive supporting program in which we traditionally combine fun activities (e.g., a brewery tour) with culinary delights. The first User Day took place in the summer of 2011. Since then, we usually invite our users once a year to meet up in Dortmund.

2012: INOSIM Supports Education at TU Dortmund University

Since 2012, the Bioprocess Simulation course has been offered as a lecture with integrated practice and final exam as a permanent cooperation between TU Dortmund University and INOSIM. The course was originally designed by Katrin Brandt while working at TU Dortmund to obtain her doctorate and before joining INOSIM. Today, she is supported by INOSIM’s Head of Foresight Solutions Dominik Wolff. The valuable contact with students resulted in several master theses and new team members for INOSIM.

In 2019, TU Dortmund has also given a teaching assignment on Chemical Production Logistics to INOSIM employee Christian Sonntag after finishing his doctorate at the Chair for Process Dynamics and Operations (DYN) at TU Dortmund.

Other universities are also supported by INOSIM to set up courses. Thus, in 2022, a new course was established at the University of Twente in the Netherlands.

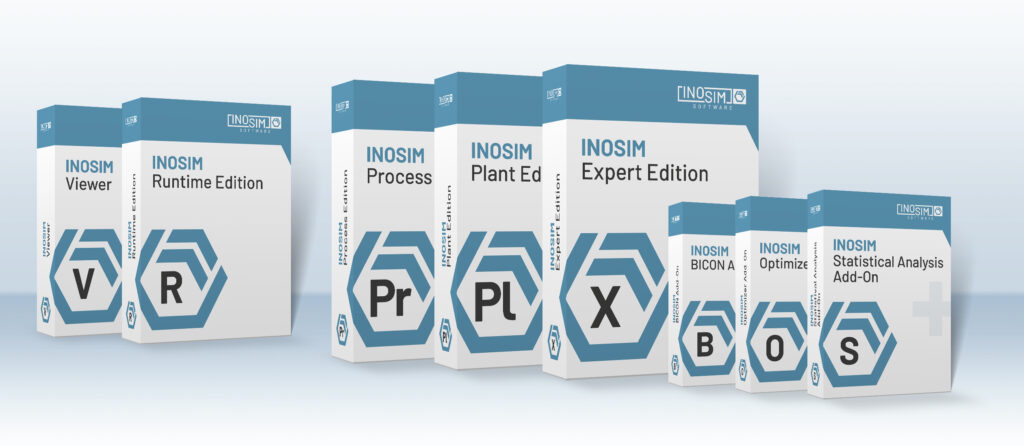

2014: Broadened Software Portfolio: INOSIM Expert, Process, and Plant Edition

Our software has been continuously updated with new features, e.g., since 2004 there is the WinWrap Basic Editor to adapt simulation models even more detailed to reality with the help of VBA code. Accompanying the INOSIM Bio project, extended material properties (phases and components) were integrated into the software in 2007. Since 2011, INOSIM offers its own layout window. With the development of the process engineering recipe modules, INOSIM splits its product portfolio and has been offering the INOSIM Expert, Process, and Plant Edition in version 11 since 2014.

Farewell to the CD: Since version 11, INOSIM is only offered for download and is no longer shipped on physical data carriers (CD).

2015: Networking In The “AK Process Simulation”

One approach initiated by INOSIM to promote the use of simulation technologies in process engineering production is the Process Simulation Working Group, which is open to all stakeholders from the industry. The participants have been meeting twice a year since 2015 (with a mandatory Corona break in 2020-2022) at different locations in Germany. The Process Simulation Working Group includes representatives of global players in the process industry as well as employees of highly specialized, smaller technology companies. During their meetings, the members of the working group exchange information on current issues and problems from the practice of process engineering, in which process simulation can be used promisingly. Project management, process optimization, plant design, environmental problems, energy and resource efficiency as well as failure and maintenance management are just some of the keywords discussed in the working group. Information on the next meeting of the working group can be found in the Events section of the INOSIM homepage or on their own website.

2016: INOSIM Summer Party

From the very beginning, everyone who works at INOSIM saw themselves as part of a family. An eventful start-up history laid the foundation for this view. Flat hierarchies, casual language, and a culture of mutual support characterize all the companies of the INOSIM Group to this day. Our corporate summer festival in Dortmund is a highlight of this community every year in September. All employees with their families or life partners are invited, regardless of whether they live in Bochum, Dallas, or Bangalore. As it is the custom in the Ruhr area, we start each party with a coffee chat, followed by a round of games (e.g., archery, mini golf, escape room etc.) before the party ends with an extended get-together in one of Dortmund’s many favorite restaurants. Outside official events, the INOSIM team also meets on the tennis court, in the football stadium, during a concert, or for mulled wine at the well-known Dortmund Christmas market.

2018: INOSIM 12 With New Gantt-Chart And File-Based Databases

A lot has changed with INOSIM Version 12: 64-bit version, access to the simulation reports via VBA, a free INOSIM Viewer, which allows viewing models and simulation results, e.g. with the completely redesigned Gantt Chart.

2018: INOSIM’s New Innovation Department

2018 saw the start of the new Innovation Department headed by Dr. Christian Sonntag. In view of the emerging opportunities and challenges surrounding digitization, Industry 4.0, and Artificial Intelligence, this branch was deliberately designed and staffed by highly qualified employees in an already innovative company. Parallel to the development work in this department, a further doctoral thesis and a new master thesis are currently in progress. At the heart of the department is the development of INOSIM Foresight, a system of applications, digital twins and interfaces with a defined goal: Based on INOSIM simulations, all production employees are provided with high-quality predictions in order to make better decisions faster in the production process.

2019: INOSIM Goes Worldwide

After process simulation with INOSIM was established in Germany and Europe from 2015 at the latest, our solutions also found increasing distribution overseas. Especially on the strong US market, INOSIM is represented with software licenses, but also with consulting projects. Therefore, INOSIM Solutions was founded in Dallas, Texas, in 2019. This was followed by INOSIM Solutions India for the APAC region in April 2022, and an office in Spain for Southwest Europe and the LATAM region in December 2022.

In addition to strengthening our foreign sales, our global network today enables us to offer our first-class support in the respective regions largely during the usual business hours in most countries.

2020: Homeoffice In Covid Times

March 2020: Germany makes acquaintance with home office and mobile working on a broad scale for the first time – but no problem for INOSIM. From our beginnings, our employees have been able to flexibly choose their place of work and receive support in setting up their workplace in their own four walls. Since the end of the pandemic, our team has been in the Dortmund office at least once, most of them several times a week – challenges are best solved together, ideally with a coffee from the new high-end coffee machine.

2021: Visualizing Simulation Results with Modern BI Tools

![]()

Our novel BICON interface for exporting simulation data extends INOSIM´s analysis capabilities by providing powerful visualizations with business intelligence solutions such as Tableau or MS Power BI. This enables the creation of clear visualizations from INOSIM data, e.g., partial plant statistics, resource allocations, mass balances, or user-defined attributes. Simulation data can thus be explored quickly and intuitively and be arranged in dashboards using multidimensional visualizations to better identify relationships. Interactive results and visualizations can be easily shared across the enterprise with business intelligence server solutions. INOSIM BICON provides sample visualizations and predefined dashboards for a user-friendly entry into the revolutionary world of BI-based simulation analysis.

2022: Successfully Finishing The OptiProd.NRW Research Project

The OptiProd.NRW project belongs to a long series of research participations that have been part of the INOSIM company portfolio from the very beginning. We believe that continuous research is an important prerequisite for the groundbreaking innovations that our customers value so much. As an innovative SME, we always keep an eye on how to translate our promising results into industrial practice.

In OptiProd.NRW, ICT experts from INOSIM Software and scientists from the Technical University of Dortmund, together with Bayer AG, developed a new software system that uses state-of-the-art methods of mathematical optimization to automatically calculate optimal production schedules. Detailed digital twins of the production plant ensure that these plans can be used directly in production without manual adjustments, saving a lot of time and costs.

Optimal production schedules will reduce the environmental impact, energy and resource consumption of the process industry. They will increase the performance of production facilities. The process industry, which is one of the largest consumers of energy and raw materials in North Rhine-Westphalia, can produce more sustainably and achieve savings of millions.

2023: INOSIM Foresight – What If You Knew The Future?

With our new solution INOSIM Foresight, the application of process simulation reaches beyond planning and engineering into the real operation of batch plants. While the plant is operating, the production processes are simulated in parallel with Digital Twins from INOSIM. In the process, the simulation constantly provides plant operators with data for predictive decision support. Thus, it is always clear what to do next, but also which malfunctions, failures or necessary maintenance steps are to be expected. INOSIM Foresight translates the data from the simulation into intuitive, manageable visualizations. For this purpose, business intelligence solutions such as Tableau or Power BI are integrated into the INOSIM process simulation via a special interface. The new solution will benefit not only production planners and managers, but also occupational groups that were previously more remote from simulation, such as production employees, plant operators and maintenance teams. First prototypes of INOSIM Foresight are already in use with our industrial development partners with good success.

INOSIM, An Established Name: Ready For The Future

Our time is facing major challenges: Digitization, Industry 4.0, scarcity of resources, shortage of skilled workers are just a few of the keywords – but also the energy transition, climate change, environmental protection and resource efficiency. INOSIM’s solutions and services can help to cope with the upcoming transformation processes around the world. Peter Balling’s vision at the beginning of the millennium has become a modern, family-run, well-established group of companies committed to continuous innovation. Our highly qualified, young and committed team plays a key role in this. Together with our customers, we are ready to shape the future and meet the challenges ahead effectively.

Do you have any questions or would like to know more about this topic? Please contact us.