The OptiProd.NRW project partners are developing a new methodology and software solution that lets you generate high-quality production schedules with the click of a button, even for the most complex of plants. And these schedules will just work – no need for expensive, error-prone, and time-consuming manual modifications.

New Scheduling Algorithm

After more than two very productive years, the OptiProd.NRW project is now on its home stretch. The new simulation-based production scheduling algorithm has been developed and matured to such a degree that it is ready for validation and demonstration on a real-world industrial case study of partner Bayer, a complex make-and-pack process plant.

Validation on a complex process

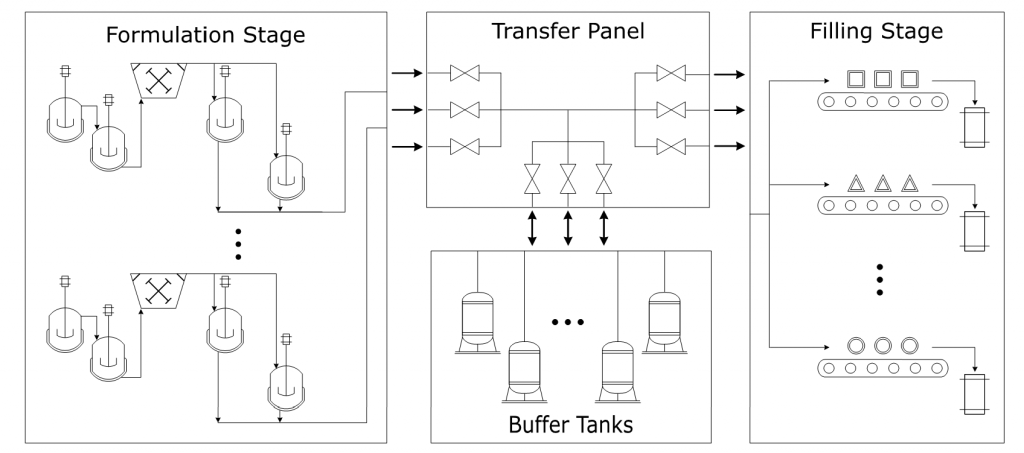

Make-and-pack process plants make up a significant slice of the total of production plants in the process industry. Their competitiveness, productivity, and resource efficiency largely depend on the quality of the production scheduling. A schematic representation of the industrial two-stage formulation and filling plant that is investigated in OptiProd.NRW is shown below. It consists of a formulation stage, which is decoupled from the downstream filling stage by a set of buffer tanks that are connected through the transfer panel. In addition, the logistics of raw materials and final products as well as the shift schedules of the operators must be considered.

Schematic representation of the industrial formulation plant

Digital Twins needed for Validation

The difficulty of such scheduling problems is the tremendous degree of detail that must be considered to guarantee the feasibility of the plans on the shop floor level. To capture the complex interactions precisely, the OptiProd.NRW partners are using Digital Twins by INOSIM. They provide a powerful and flexible formalism to capture the features of industrial production processes and can be configured via an easy-to-use interface that enables the design of models without deep knowledge on simulation. The INOSIM software can simulate simple scheduling rules, but mathematical optimization of schedules is not (yet) offered.

OptiProd.NRW on the road to Success

Until the project finishes at the end of 2022, the partners will focus on real-world validation and demonstration of the new scheduling solution on the industrial use case described above, as well as on dissemination and exploitation. After the end of the project, INOSIM intends to quickly commercialize the new production scheduling solution.