The Process Simulation Working Group sees itself as an open committee for engineers interested in simulation. At the biannual meetings, the focus is on an open–to–technology exchange on the diverse application areas of process simulation and its challenges in practice. This time, the use of generative AI in engineering and simulation was discussed.

On October, 2, 2025, the 15th meeting of the Process Simulation Working Group (AKPS) took place in Würzburg. This time, the meeting was hosted by SIGMA Process & Automation GmbH, a member of the ZETA Group, just like INOSIM.

The evening before: Franconian hospitality

Twenty-eight interested experts from the fields of chemistry, pharmaceuticals, food, and engineering (coming from Austria, Germany, the Netherlands, and Switzerland) gathered for the working group meeting in Würzburg. On Wednesday evening, the group met for a casual get-together at a traditional inn right on the banks of the Main River, where participants were treated to authentic Franconian specialties. As usual with the working group, there were already many opportunities for exchange and networking here.

A hearty start: The enthusiastic discussion among 25 “simulators” began the evening before

What does the introduction of AI mean for classical engineering?

The actual meeting of the Process Simulation Working Group on the following Thursday had been chosen to focus on Generative AI in Engineering & Simulation. In the morning, a keynote by host representative Jannick Richter (SIGMA) set the thematic framework: GenAI in Industry: The end of mass engineering?

Jannik Richter (SIGMA) highlighted the opportunities and pitfalls of using AI.

Where AI (currently still) hits its limits: Modeling uncertainties

Michel Kunkler (TU Munich University)

Michel Kunkler from the TUM School of Computation, Information and Technology first provided an overview of business process modeling and the application of these simulation models, offering the audience from the world of (production) process simulation a new perspective on familiar technology. The presentation highlighted that data-driven approaches often require large amounts of data, which are not always available. GenAI could offer a solution by integrating common knowledge to reduce epistemic uncertainties and better modeling of complex relationships. Michel Kunkler led through this complex topic with a wink using the example of “Horst”, who visits the regulars´ table every other Thursday of the month, a behavior which somehow affects his work performance on the following Friday…

TU Munich: More effective brewing with the chatbot

Günther Gaßner (TU Munich University)

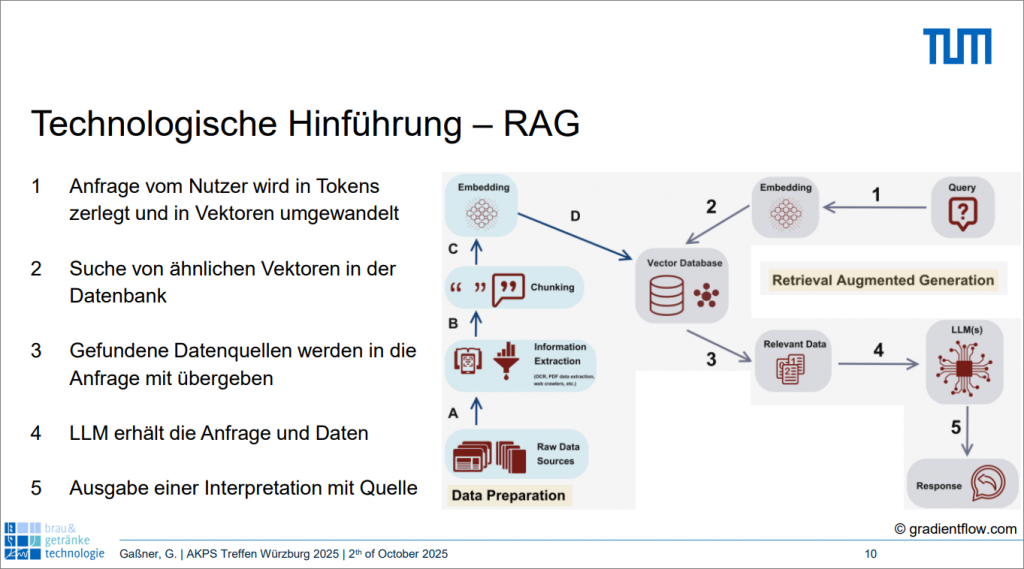

Using the domain of brewing science, it was demonstrated how AI can improve knowledge management in an industrial sector. A dedicated chatbot (ChatBGT) was developed at the Chair of Brewing and Beverage Technology (BGT) at the Technical University of Munich with the goal of generative knowledge preparation. Günther Gaßner provided an introduction to the current state and current challenges in knowledge management. A detailed presentation of generative knowledge processing with the help of AI followed, in which participants were introduced to concepts such as LLM (Large Language Model) or RAG (Retrieval Augmented Generation) and were illustrated through practical application on the chatbot. Possible applications in the brewing sector would then be, for example, process descriptions, recipes, maintenance documentation, machine or laboratory manuals, operating or occupational safety instructions. The use of AI thus helps to secure company knowledge, lay the foundation for future technologies (A2A, SLM, MCP), and ultimately “enable brewers to focus on brewing”.

Comprehensible slides explained the new technical terms from AI (Image: Gaßner/TUM)

Clarity at Clariant: AI Clarita

Malte Otromke (Clariant International Ltd.)

To introduce the use of AI at Clariant, speaker Malte Otromke let it speak for itself:

I am Clarita, the AI assistant of Clariant, a leading specialty chemicals company, and I can help with questions about chemical processes, calculations, and technical information. My strengths lie in providing precise answers to inquiries, performing complex mathematical calculations, and providing clear, informative responses to a wide range of topics. As a digital assistant, I am designed to provide professionals in the field of process simulation and chemical engineering with current information and analytical support.

Chatbot “Clarita” has a face and can speak (Image: Clariant)

Clariant´s AI uses pre-trained models and can be further trained with project-specific information. Furthermore, there are different variants of the AI assistant (e.g., General, Project Specific, Research, Sales, Operations, Production). Conclusion: AI offers engineers a variety of benefits, accelerating their entry into new topics, handling routine tasks, or preparing data.

INOSIM: Will INO-SIMon take over your job?

Engelbert Pasieka, Dominik Bleidorn (INOSIM GmbH)

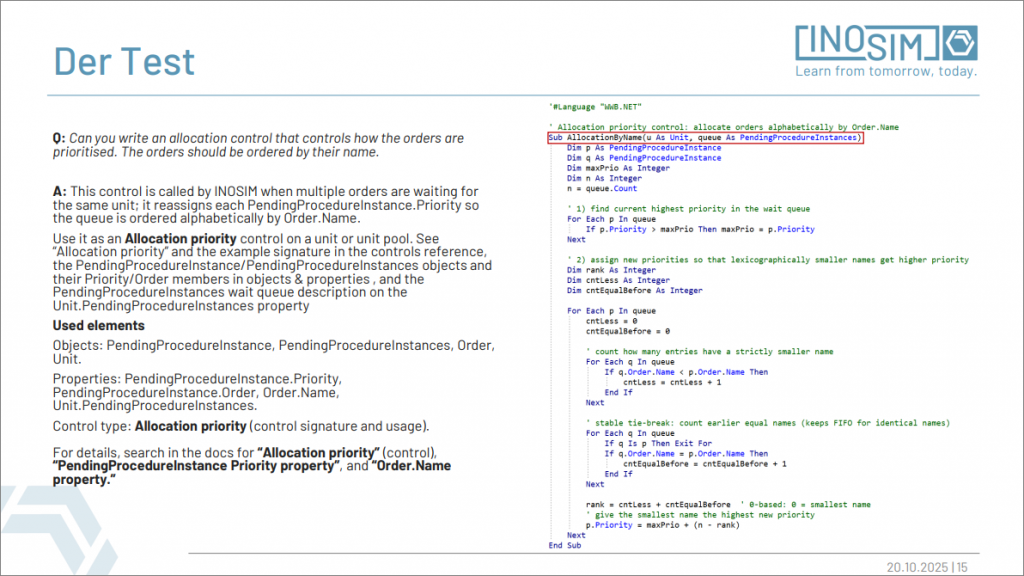

At INOSIM, knowledge management was chosen as the first application area for the development of an in-house chatbot. The content basis for this is the INOSIM user documentation with the Basic Object Model, the INOSIM Tips and Tricks library, and a collection of Docs for Advanced Scripting (VBA). The development goal was to ensure the secure and flexible integration of the bot: customers use their own chatbot license, and INOSIM provides the interface and data. Scripting in INOSIM enables the control of events in the simulation and is based on WinWrap VBA and .NET 5 libraries. It includes hundreds of controls, constants, events, objects, methods, and properties. This is intended to make the bot (codename “SIMon”) easily accessible to users and answer questions about specific objects (e.g., “How do I program a custom allocation control in INOSIM?”) and generate code snippets. For the prototype, the documentation was prepared for interpretation in an LLM and corresponding system prompts were developed to prevent “invention”. The results are promising, but expensive due to the large “Context Length”. Therefore, Retrieval-Augmented-Generation (RAG) was also experimented with, and valuable insights were gained about the possibilities and limitations of applying LLMs for future developments.

Early tests demonstrated how the INOSIM chatbot would work

Hands-on- workshop

From the presentations to the experimental implementation of the learned topics it is always just a small step for the Process Simulation Working Group. This time, the joint workshop was held under the motto Prompt-Engineering of naive and structured prompts. It involved writing a prompt, i.e., the task to be completed by the AI, into an input field, for example, as a question. One or more tasks are converted into a prompt-based dataset and a language model is trained using what is known as prompt-based learning. Two tasks were specifically tested in practice: writing Python code with ChatGPT, Gemini, or a company’s AI, as well as using the INOSIM Bot for INOSIM VBA code and support. This allowed participants to gain practical access to the topics presented in the lectures.

Gaining insights and shared learning across company boundaries at the final workshop

Outlook for the next meeting

The next Process Simulation Working Group is planned for spring 2026. You will receive more detailed information soon here on the INOSIM homepage and on the Homepage of the Working Group. We are looking forward to receiving your registration and inviting you to the next meeting!

Do you have any questions or would like to know more about this topic? Please contact us.